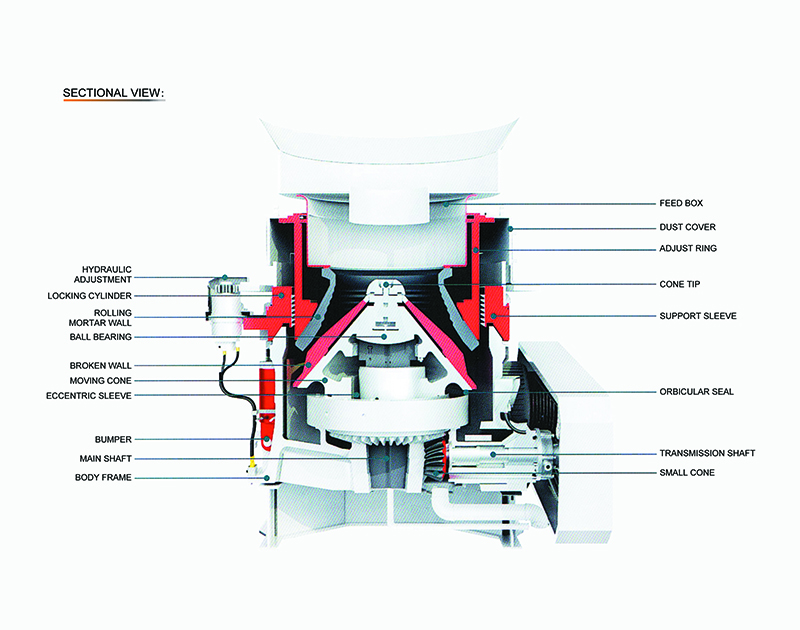

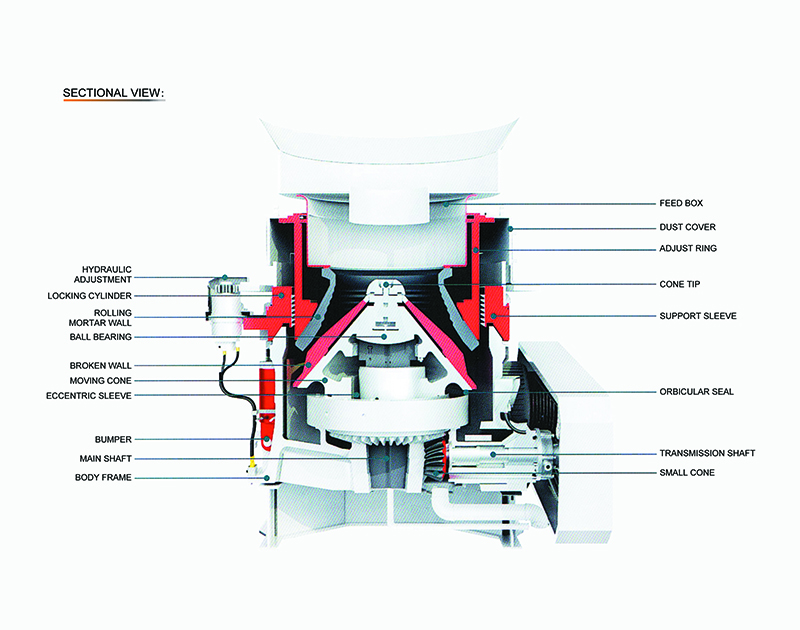

The HPD multi cylinder hydraulic cone crusher, like the single cylinder hydraulic cone crusher, has the following characteristics due to the use of hydraulic devices for safety, adjustment, and locking: easy adjustment of the discharge port, low overload coefficient when passing through non crushing objects, and easy removal of non crushing objects blocked in the crushing chamber. Production practice has shown that this hydraulic cone crusher has good performance.

The HPD multi cylinder hydraulic cone crusher uses a hydraulic system to adjust the size of the crusher discharge port, which can effectively ensure the safe operation of the equipment. When there is a foreign object in the crushing chamber, the hydraulic system can automatically retract the moving cone. After the foreign object is discharged, the system will automatically reset the retracted moving cone and maintain its original position at the discharge port to continue working.

Product features:

1. Increase eccentricity to improve processing capability:

2. Accelerate speed, increase power, and improve crushing strength;

3. Raise the selection center of the moving cone and optimize the cavity design;

4. Thickening the lining plate to extend its lifespan;

5. Replace the hydraulic push rod device with a hydraulic motor, and remove the fixed cone assembly in 10 minutes;

6. High production and ore content:

7. The key components are made of high-strength materials, with an appropriate increase in weight for higher reliability;

HPD multi cylinder cone crusher is a typical crushing equipment for medium and fine crushing of hard materials. During operation, the moving cone rotates and swings along the inner surface. Near the fixed cone, the material is crushed by the pressure and bending of the moving cone. At the deviation from the moving cone, the crushed material falls from the bottom of the cone due to the gravitational force, and the entire crushing process continues along the inner surface in sequence. The locking protection cylinder section consists of thousands of locking protection cylinders, over iron protection accumulators, buffer accumulator groups, and operating circuits. The locking protection cylinder mainly serves to protect the iron and clean the crushing chamber. Every two hydraulic cylinders are equipped with a buffering head energy device, which is used to absorb the adjustment ring jumping impact caused by a small amount of hard material during normal crushing.

Technical parameters:

production capacity |

Model | 6mm | 8mm | 10mm | 13mm | 16mm | 19mm | 22mm | 25mm | 32mm | 38mm | 45mm | 51mm |

HPD 300 |

| 85-120 | 115-140 | 150-185 | 180-220 | 200-240 | 220-260 | 235-290 | 250-320 | 300-380 | 350-440 |

|

HPD 500 |

|

| 200-250 | 230-290 | 280-350 | 320-400 | 345-430 | 370-460 | 405-535 | 445-605 | 510-700 | 580-790 |

HPD 800 |

|

| 260-335 | 325-425 | 385-500 | 435-545 | 470-600 | 495-730 | 545-800 | 600-950 | 690-1050 | 785-1200 |

Technical parameters:

Specification and parameter table |

Model | Type | Open edge feeding port size (mm) | Tight edge feeding size (mm) | Minimum discharge port size (mm) | processing capacity (t/h) | Maximum installed power (kw) | Weight (t) |

HPD300 | C1 | 265 | 230 | 25 | 220-440 | 250 | 26 |

C2 | 240 | 210 | 20 | 190-380 |

M | 190 | 150 | 16 | 175-320 |

F1 | 145 | 105 | 13 | 110-260 |

F2 | 120 | 80 | 10 | 100-240 |

HPD500 | C1 | 370 | 330 | 38 | 425-790 | 400 | 50 |

C2 | 320 | 290 | 30 | 380-700 |

M | 245 | 210 | 22 | 330-605 |

F1 | 180 | 130 | 16 | 270-535 |

F2 | 150 | 95 | 13 | 200-430 |

HPD800 | C1 | 375 | 350 | 38 | 545-1200 | 630 | 90 |

C2 | 340 | 300 | 32 | 495-1050 |

M | 310 | 265 | 25 | 470-950 |

F1 | 265 | 220 | 17 | 385-730 |

F2 | 210 | 150 | 14 | 310-600 |