The HPL vertical shaft impact crusher is a high-efficiency crushing equipment developed by our company through the introduction of international advanced technology and combined with the actual situation of domestic sand production. It is widely used in industries such as high-grade highways, railways, water conservancy, construction, cement, refractory materials, metallurgy, glass sand, concrete mixing plants, and sand and gravel yards.

Product features:

1. High production efficiency: After optimizing the design of the deep cavity rotor of the HPL vertical impact crusher, the material throughput has been increased by about 30%, resulting in an increase in output.

2. Excellent finished sand particle shape: The processed finished sand particle has a beautiful shape, reasonable grading, and adjustable fineness modulus, which better enhances its practical value.

3. Long service life and convenient maintenance: The hammer head component of HPL vertical impact crusher can be adjusted and exchanged for use, which reasonably extends the service time and is also very easy to maintain.

4. Environmental protection in place: adopting deep cavity turbine design to reduce dust pollution; Simultaneously selecting a good exhaust system and high-efficiency dust removal equipment, with multiple functions, enables more reasonable and effective control of dust pollution; In addition, the equipment runs smoothly, reduces body vibration, and better controls startup and operating noise within environmental standards.

Working principle:

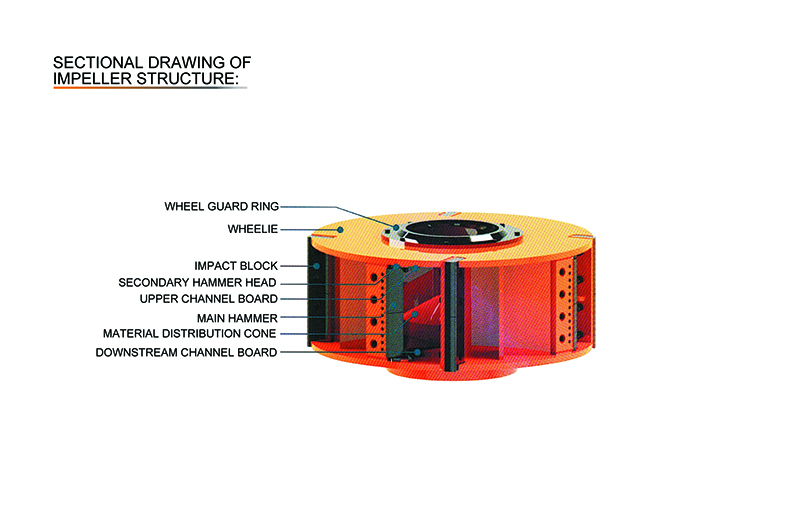

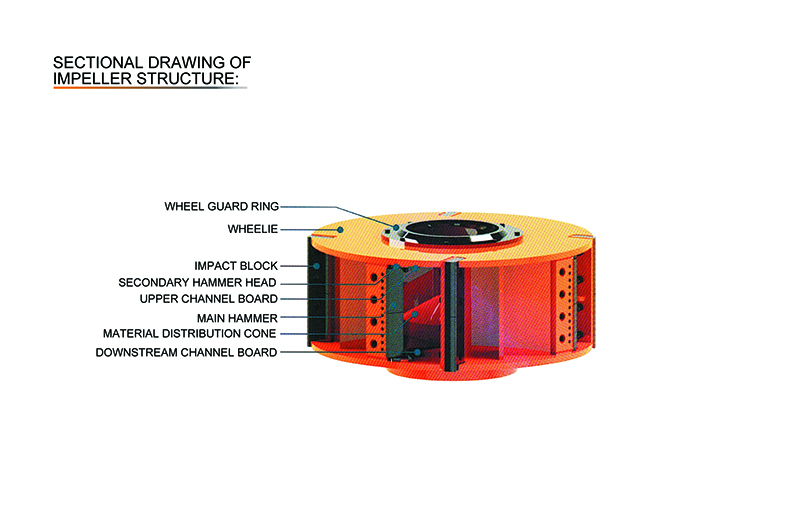

The HPL vertical axis impact crusher has two feeding methods, namely central feeding and central feeding accompanied by annular waterfall feeding. The operating principle is as follows: the HPL crushing chamber adopts the principle of impeller crushing, where materials enter the crushing chamber from the feeding port and are accelerated and thrown out by the impeller, with a speed that can reach tens of times the acceleration of gravity. After the material is thrown out, it collides with the freely falling material, achieving first level crushing. Then, the material hits the counterattack plate or the lining plate inside the crushing chamber together, and is bounced diagonally upwards to the top of the vortex chamber. After that, it changes its direction of motion, deflects downwards, and collides with the material emitted from the impeller channel to form a continuous material curtain. The material is subjected to two or more impacts, friction, and grinding in the crushing chamber, and the crushed material is discharged from the lower discharge port.

Technical parameters:

Model | Sand making | Change Shape | Sand making | Change Shape | Spindle speed (r/min) | Motor power (kw) |

Maximum feed particle size (mm) | Processing capacity (t/h) |

HPL7515 | ≤30 | ≤40 | 70-140 | 150-280 | 1500-1700 | 75×2 |

HPL8522 | ≤35 | ≤45 | 120-190 | 240-380 | 1500-1700 | 110×2 |

HPL9532 | ≤40 | ≤50 | 180-280 | 350-540 | 1300-1510 | 160×2 |

HPL1150 | ≤45 | ≤55 |

340-360

| 410-660 | 1000-1300 | 250×2 |

HPL1263 | ≤50 | ≤60 | 450-480 | 540-870 | 1000-1300 | 315×2 |