The HPZ series single cylinder hydraulic cone crusher is a new type of high-efficiency crusher independently developed and designed by our company based on more than 20 years of experience in the crushing industry, production, sales, and service, combined with modern technological development and market demand, and widely absorbing advanced technology from countries such as Finland and Germany. Widely used in industries such as metal and non-metal minerals, cement, sand and gravel, metallurgy, etc., suitable for various ores and rocks with medium to high hardness, such as iron ore, non-ferrous metal ore, granite, basalt, quartzite, pebbles, sandstone, limestone, etc.

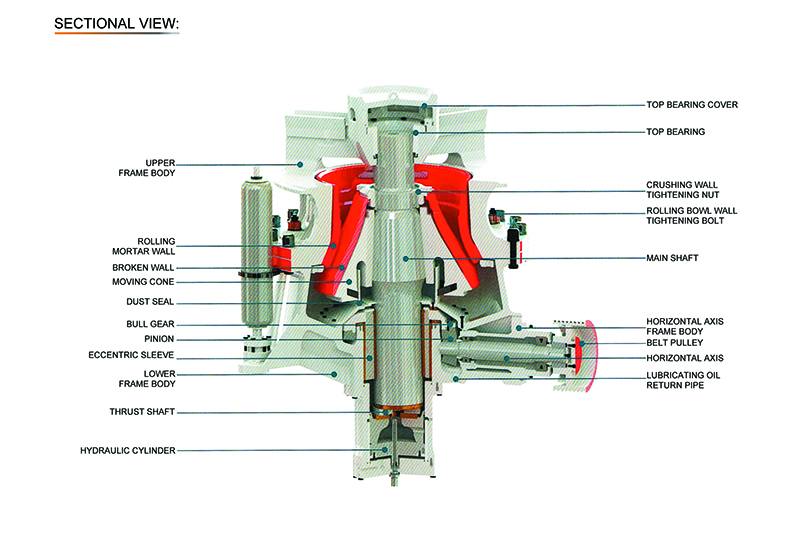

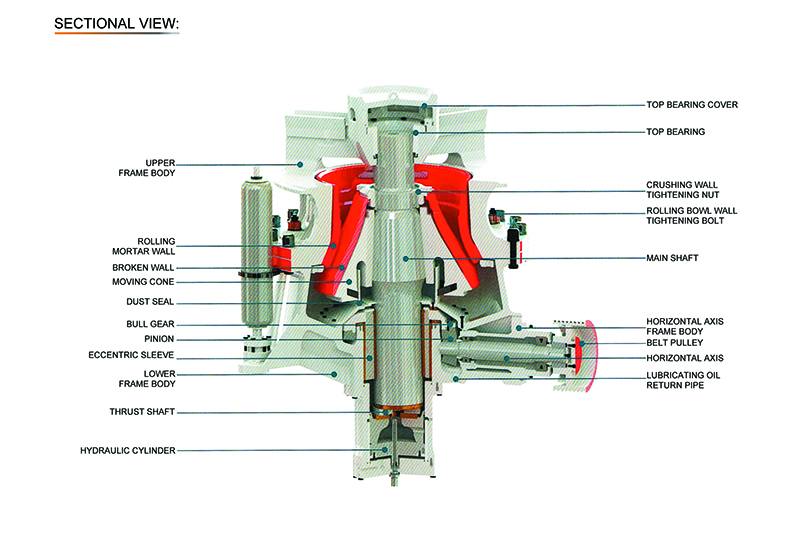

Working principle:

The horizontal shaft is driven to rotate by an electric motor, and the horizontal shaft is driven to rotate by an eccentric sleeve through gears. The eccentric sleeve then drives the conical part to perform conical oscillation, thereby achieving continuous crushing and crushing of stones. By adjusting the hydraulic cylinder located at the bottom of the moving cone, the moving cone can be moved up and down, making it easy to adjust the size of the ore discharge and the particle size of the product. At the same time, the hydraulic cylinder also provides iron protection function. When an unbreakable object (such as an iron block) enters the crushing chamber, the hydraulic cylinder automatically causes the moving cone to fall, releasing the iron block to protect the crusher. After the foreign object is discharged, the moving cone automatically returns to its original position, and the equipment resumes working state and continues to crush.

Technical parameters:

Model | Type | Feed particle size (mm) | Stroke | Production | Motor Power (KW) | Total weight (T) |

8mm | 10mm | 15mm | 20mm | 25mm | 30mm | 35mm | 40mm |

HPZ

160 | EF | 40 | 18mm | 40-50 | 45-55 | 60-70 | 80-90 | 85-95 |

|

|

| 90 | 8.5 |

F | 50 |

MF | 100 | 20mm | 50-55 | 50-60 | 70-80 | 95-105 |

|

|

|

|

M | 130 | 25mm |

| 55-65 | 75-90 | 105-120 |

|

|

|

|

C | 150 |

HPZ

260 | EF | 40 | 18mm | 60-70 | 70-90 | 80-105 | 100-125 | 135-150 | 160-175 | 185-200 |

| 160 | 13.5 |

F | 70 | 25mm |

| 90-110 | 110-130 | 130-155 | 160-180 | 185-210 |

|

|

M | 130 | 32mm |

|

| 140-160 | 170-190 | 190-220 |

|

|

|

EC | 210 | 40mm |

|

|

| 200-220 | 220-240 |

|

|

|

HPZ

360 | EF | 40 | 25mm | 100-120 | 110-130 | 135-155 | 160-180 | 190-210 | 210-235 | 240-260 |

| 250 | 18 |

F | 60 |

MF | 100 | 32mm | 110-130 | 120-150 | 165-195 | 195-225 | 230-260 | 265-295 | 300-330 |

|

M | 130 |

C | 180 | 40mm |

| 150-170 | 205-235 | 245-275 | 290-320 | 325-355 |

|

|

EC | 260 |

HPZ

560 | EF | 50 | 25mm | 140-160 | 160-180 | 190-210 | 240-260 | 270-290 | 310-330 | 330-360 | 360-380 | 315 | 26.5 |

F | 90 |

MF | 130 | 32mm |

| 210-230 | 230-250 | 270-290 | 310-330 | 340-370 | 380-410 | 430-450 |

M | 180 |

C | 220 | 40mm |

|

| 290-310 | 320-340 | 380-410 | 430-460 | 480-510 |

|

EC | 280 |

HPZ

660 | F | 100 | 25mm | 180-210 | 190-220 | 210-250 | 240-270 | 270-310 | 310-360 | 340-380 | 370-410 | 355 | 31 |

MF | 140 | 32mm |

| 240-280 | 260-300 | 290-330 | 320-360 | 350-400 | 390-440 | 440-500 |

M | 190 |

EC | 300 | 40mm |

|

| 300-330 | 330-370 | 370-420 | 410-500 | 480-550 | 530-630 |

HPZ

860 | F | 110 | 32mm |

| 300-420 | 330-560 | 360-610 | 400-680 | 455-720 | 510-760 | 560-810 | 630 | 50 |

MF | 150 |

M | 240 | 40mm |

|

| 380-630 | 410-720 | 460-820 | 530-910 | 580-940 | 640-990 |

EC | 340 |