The HPX high-efficiency hydraulic gyratory crusher is a new type of high-efficiency crusher independently developed and designed by our company based on more than 20 years of experience in the design, production, sales, and service of the crushing industry, combined with the development of modern industrial technology and extensive absorption of advanced crusher technologies from the United States, Germany, and other countries. The HPX high-efficiency hydraulic gyratory crusher integrates mechanical, hydraulic, electrical, automation, intelligent control and other technologies, representing the world's most advanced gyratory crusher technology. It has many advantages that traditional crushers cannot compare with, such as high crushing efficiency, low production cost, easy maintenance and adjustment, and can meet various requirements of customers for efficient coarse crushing operations.

Performance characteristics:

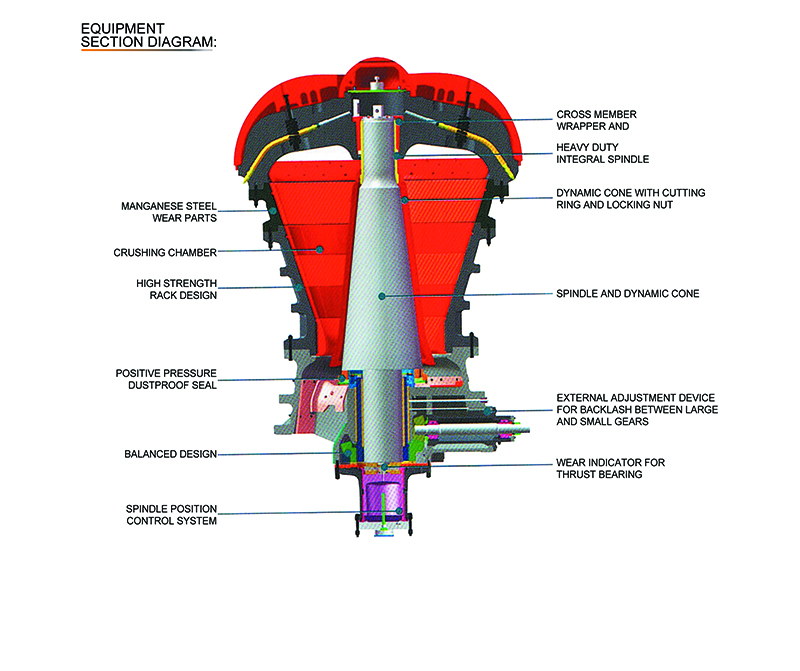

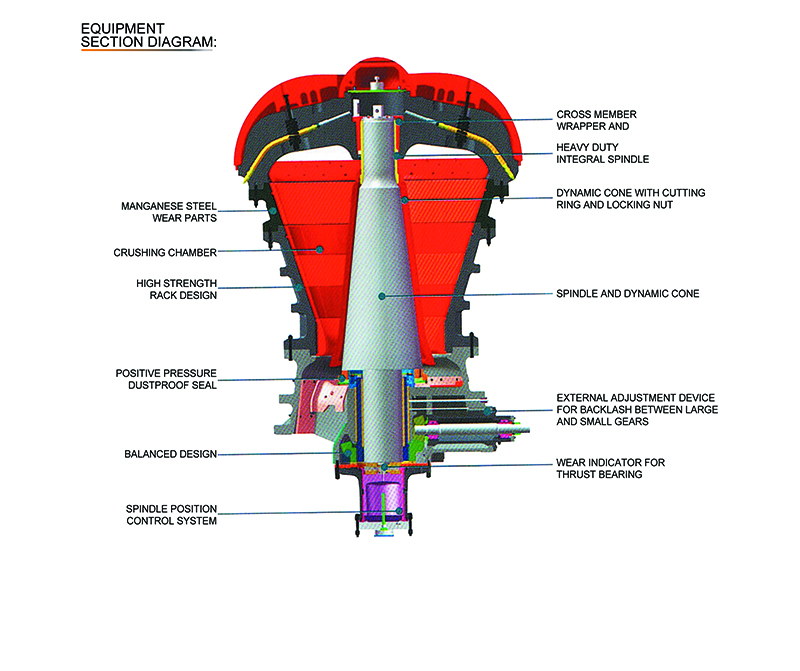

1. Lower crushing cost: The large inclined crushing chamber and longer crushing surface enable the crusher to have ultra-high crushing capacity, and the lifespan of the lining plate is maximized. The ultra heavy frame, large-diameter integral spindle assembly, and high-performance bearings ensure longer service life and safer and more reliable operation. Fine crushing chamber design ensures optimal production capacity. By simply replacing the eccentric sleeve and changing the processing capacity of the crusher, it can meet the different configuration requirements of the entire crushing plant.

2. Easy adjustment: The ore discharge adjustment system adopts hydraulic adjustment method to compensate for

liner wear and control product particle size. The position of the spindle can be intuitively displayed through the touch screen, which is convenient for maintaining the stability of the crusher discharge port, keeping the output constant, and monitoring the wear of the lining plate.

3. Convenient maintenance and repair: equipped with automatic lubrication, heating, cooling, and circulation systems; Automatic spindle position control system: convenient external backlash adjustment device. We can provide a hydraulic crossbeam separator for the disassembly of crossbeams during operation.

4. Heavy duty spindle design: Adopting an integrated forged spindle design, it avoids the danger of loose cones and reduces downtime. The dynamic cone nut pattern is located on the replaceable alloy steel sheath of the spindle, which does not cause stress concentration on the spindle, increases the strength of the spindle, and extends its service life. The upper shaft neck has a large diameter and ultra-high strength, which can avoid adapting to harsh crushing conditions. 5. Other features: The crossbeam bushing and seal can be easily replaced without removing the crossbeam, reducing manpower, time, equipment consumption, and production loss caused by parking. The high-strength frame design ensures trouble free operation, extends service life, and effectively prevents dust from entering through dust-proof sealing, prolonging the life of the crusher bearings.

Technical parameters:

Model | Feeding port size (mm)

| Recommended maximum ore size (mm) | Minimum size of ore discharge outlet (mm) | Adjustment range of discharge port (mm) | Bottom diameter of moving cone (mm) | production capacity (t/h) | Motor Power (kw) |

HPX900 | 900 | 750 | 130 | 130-160 | 1650 | 600-1000 | 280 |

HPX1200 | 1200 | 1000 | 160 | 160-190 | 2000 | 1200-1500 | 400 |

HPX1400 | 1400 | 1200 | 170 | 170-220 | 2200 | 2750-3300 | 560 |

HPX1600 | 1600 | 1350 | 190 | 190-215 | 2362 | 3700-4500 | 800 |